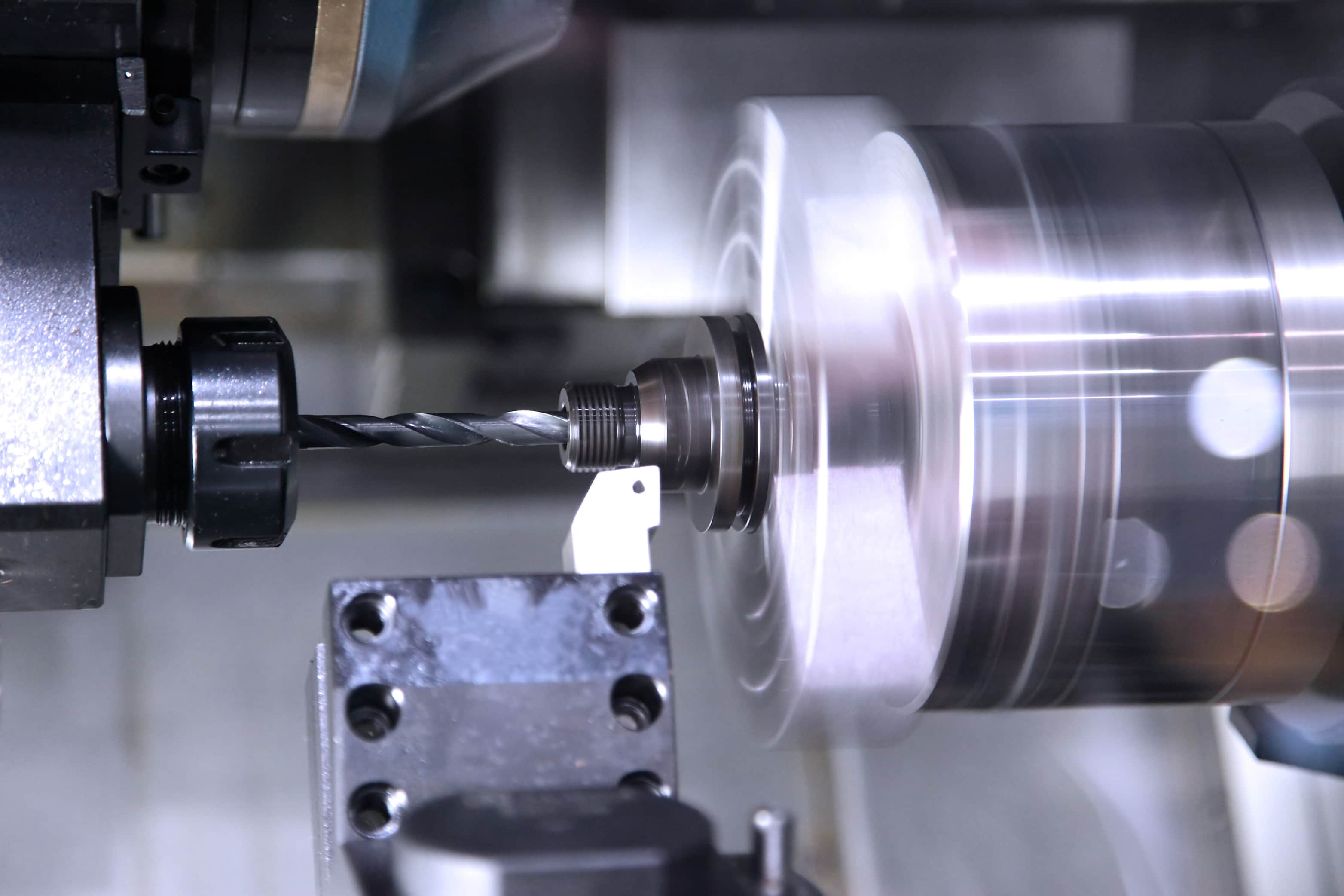

At C&N Manufacturing we proudly offer precision CNC machining services for customers across a spectrum of industries.

Our services are ideally suited for aerospace sensors and controls, precision valve components, military and defense, and transportation applications. Our state-of-the-art, ISO certified facility is outfitted with the latest 3 axis CNC milling and 5 axis lathes which feature live tooling. We can create custom parts from a wide variety of materials, including alloy steels, carbon steels, plastics, aluminum, stainless steel, brass, exotic metals and engineered plastics, glass filled nylon, ultem, and vesper among others.

Part sizes of up to 20” in width, 20” in height, and up to 17” in diameter are possible, with lengths of up to 40” for milled parts, up to 3’ for turned parts. A number of processes are carried out to achieve customer specified contours, including milling, turning, broaching, facing, internal and external threading, boring, drilling, counterboring, countersinking, pocketing, reaming, and tapping, all to tolerances of ± 0.0001”.

We offer a comprehensive manufacturing experience, providing an expansive list of secondary machining capabilities including rotary broaching, knurling, honing, wire and electrode EDM machining, and surface, OD, ID, and centerless grinding. Additional value-added services include heat treating, coating, painting, plating, passivating, and assembly. Documentation, final inspection, and MPI inspections are also available.

We cater to prototype, low, and medium production volumes, handling 1 to 10,000 units. Typical turnaround times are 3 weeks, with rush and emergency services available. For more information about our CNC manufacturing capabilities or other premium services please see the table below, view Full Capabilities Statement or contact us directly.

Call:

Call: